Time to read: 7 min

You’ve envisioned it, you’ve modeled it, and you’ve printed it. As it turns out, however, your newly printed prototype may need a bit more TLC before it appears, or functions as intended. 3D printed part finishing often involves a cleaning step to improve appearances or remove unwanted support material.

The quick answer on how to clean up 3D prints?

To clean up 3D prints, remove support material, sand surfaces, and apply finishing treatments. Start by trimming supports with flush cutters, then sand the print using progressively finer grits (e.g. 200–1000). For plastic prints, use a heat gun to smooth or apply a primer and paint. Resin prints require isopropyl alcohol rinses and UV curing. Always match the cleanup method to the material and print process.

The purpose of this article is to investigate practical methods for cleaning up 3D printed parts, as well as the tools you should have at your workbench to make these processes as simple as possible. Even when outsourcing 3D printing to a partner such as Fictiv, you will likely want to perform some 3D printed part cleaning yourself.

Luckily, except for specialty appliances that can be used for dual-extruder printers with soluble support material, everything you need to get a great finish to your printed components can be conveniently found at your local hardware store.

Disclaimer: always utilize caution when performing 3D printed part cleaning. Always wear appropriate PPE to protect yourself when working with tools or chemicals of any type (for example goggles and gloves).

Part Removal

One of the most basic 3D print cleaning tools you should have in your 3D printing area is a simple putty knife. A putty knife can have many applications from the initial removal of a 3D printed part to the removal of residue from the print bed. For selecting, a putty knife, choose one with a thin, flexible metal blade to allow you to easily get between the plastic and the printer bed. This allows you to gently pry completed prints off the print bed while minimizing the risk of damage to the part.

Pro Tip: If you’re using a glass build bed with glue for adhesion, try placing your bed in the freezer for 15-20 min. The lower temperatures help to desolidify the bond of the PLA to the bed and your PLA part will pop right off!

Rough Cleaning and Part Preparation

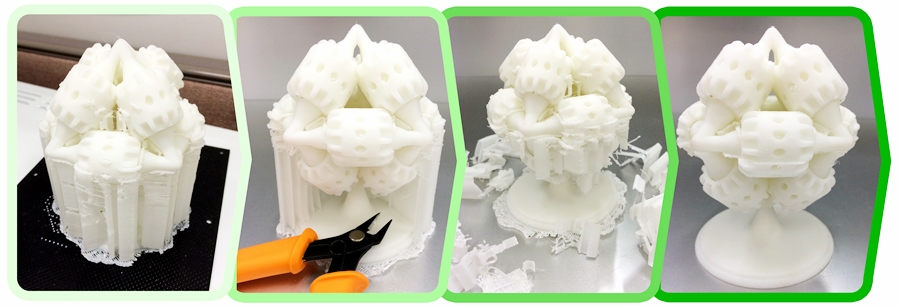

Depending on the type of part and printing method you’ve used, the first thing you’ll want to do is remove any support material adhering to the 3D printed part. There are several methods for removing this material.

Soluble Support Materials

If the printer you’re using creates part supports using a soluble material, soaking the part in hot water with a strong detergent (always following the manufacturer’s recommendations) for several hours, depending on the part size, may be sufficient for support removal.

A sodium hydroxide bath can also help dissolve support material such as HIPS.

Agitating the solution with a pump to ensure constant fluid movement over the surface of the part will also be important in processing these types of components.

Ultrasonic tanks are useful for cleaning soluble support material from complex components with a large surface area. These may clean components faster and with greater success than a simpler agitated bath because of the mechanical energy generated by the ultrasound waves. There are a variety of ultrasonic cleaners for 3D/resin printed parts. Ensure the ultrasonic cleaning chemical utilized will not attack the 3D printed base material, while effectively and completely removing support material.

Consult your 3D printer manufacturer or support material manufacturer for additional information regarding the necessary equipment or procedures to remove soluble support material from your 3D printed parts.

Single-Extruder Systems

For single-extruder type 3D printers, where support material is printed using the same material that comprises the part itself, start by removing as much material as possible using your hands or a pair of needle-nose pliers.

Many common tools can be repurposed into 3D print cleaning tools. A small pair of flush-cutters, used for cutting wire, may also come in handy during this process.

Additionally, a small set of files and dental tools can help reach those nooks and crannies that are hard to reach. Or, even a rotary/multi-tool may be beneficial in removing excess support material. Try increasing the speed of the rotary tool before increasing the torque, as speed increases will yield better results. Rotary sanding tools are not recommended for PLA smoothing. When smoothing PLA, sandpaper with a manual approach is better.

Depending on your settings, the material, and the algorithms implemented in your printing software, the bulk removal of support material can be quite easy or possibly quite frustrating. So, patience and a desire to learn the optimal settings are key here.

Pro Tip: A simple handheld scratch awl can also be very useful for cleaning out small holes, channels, and crevices in printed parts.

Tackling the Crude Imperfections

Following any major operations using pliers and cutting tools, many 3D printed parts will still have undesirable imperfections, including “strings” of material extending from the outer surfaces and rough edges where the support material has broken away from the part.

In these cases, consider carefully sanding the rough surfaces of the part using sandpaper. Start with a rough grit such as 150 to take care of major imperfections and work your way to 600 grit.

It’s worth it to use this sanding method as the finer paper generally isn’t suitable for treating coarse surface imperfections, yet coarse paper alone may leave deep scratches.

Wet-sanding plastic using 600 or 800 grit paper can produce a smooth finish on flat surfaces.

Pro Tip: Check out our Ultimate Guide to Finishing 3D Parts for more detail on how to create a perfect finish.

For more accuracy on smaller external features, use a set of micro files, often used for jewelry applications.

A rotary tool with sanding and polishing bits can also be very useful for hard-to-reach surfaces that require sanding.

Take care not to sand away areas of the part itself, particularly with electric tools! At high RPMs, you may risk slightly melting areas of the part due to heat generated from friction, so practice on spare parts first if possible.

For many engineers, cleaning your 3D printed parts can be time-consuming to get just right. Fictiv’s on-demand 3D printing services and network of highly vetted 3D printing operators deliver the highest quality parts that are printed, inspected, and ready to integrate into your next build or rapid prototyping cycle. To get an instant quote, create your free account here.

Working Out the Small Details

After you’ve taken care of the major imperfections, you may be left with areas of the part which have sand marks or other discoloration. Depending on the material, there are several ways of cleaning up these areas.

Heat Gun

A heat gun is a useful tool for very slightly melting the part you’re cleaning. This can be used to clean up the discolored patches of material you might find, for example, in PLA or ABS after a sanding operation.

Be very careful here as you can deform or melt away features in your part when using any form of heat treatment as the melting temperatures of some 3D printing filament can be relatively low. Apply hot air from the heat gun in a sweeping motion several inches from the surface of the component, checking to be sure you aren’t causing damage.

Polishing Bits

You might also consider experimenting with polishing bits, used for buffing ceramics or metals, to smooth out surfaces on 3D printed parts.

Acetone

Finally, for ABS parts, acetone can be used to create a smooth, glossy finish. When placed in a jar containing acetone vapor, the exposed surfaces of the printed part will dissolve over time, reducing the appearance of layer lines. Please note acetone is not a recommended PETG smoothing chemical.

Note that the surface of an acetone vapor-treated part will continue to dissolve for some time after it’s been removed, so it’s a good idea to practice on a few spare parts before trying this method on production components.

Also, be sure to follow standard safety protocol when using acetone. Only handle it outside or in a well-ventilated space as the vapors are harmful and keep it away from flame or excessive heat since it’s also very flammable. Refer to an acetone MSDS for more details.

3D Part Cleaning Tool List

Lastly, here’s a list of some of the recommended tools mentioned in this article to help you get started building your 3D part cleaning inventory:

- Wide and narrow flexible metal putty knives

- Needle-nose pliers

- Scratch awl

- A pair of small flush-cutters

- Sandpaper (150-800 grit)

- Micro file set

- Rotary tool with sanding/polishing bits

- Heat gun

- Acetone

- Wax carving tools

Quick 3D Part Cleaning Facts

- 3D printed part cleaning can range from utilizing common tools for material removal, sanding/chemicals for smoothing, heat guns, or polishing bits. Generally, part cleaning includes mechanical removal, sanding, and polishing. Optimal methods depend on material usage. Always consult material-technical datasheets for information.

- PLA is a common filament and it is simple to clean with mechanical tools, files, heat guns, sandpaper, and polishing tools. Resin or a clear spray paint may be utilized for an even smoother, shinier finish.

- ABS is another commonly used filament and it can be smoothed with a process known as vapor smoothing. This process involves suspending the ABS printed part above an ABS bath in a well-ventilated area for around 15-20 minutes. The vapors physically smooth the prints.

- Keeping your 3D printing bed clean is optimal for subsequent printing. Cleaning will depend on the bed material as some will be easily cleaned with IPA (PEI beds) or acetone (PEI beds) and others will need to be mechanically scraped (glass beds) with tools.

As always, feel free to reach out to the Fictiv Team at help@fictiv.com with any additional questions!